IL200

Partner: Innolite GmbH

Segment: CNC-Machines

Process: Turning

Segment: Ultra-Precision

Consistent development of Innolite machine technology has led to the new IL200. This machine features unique wireless technology for precise movement, achieving surface roughness values <0.5 nm Ra. With an innovative air bearing spindle spinning at 18,000 RPM, it offers high efficiency for producing items like infrared lenses. Using lightweight ceramic-based slides, the IL200 combines the speed of Fast Tool systems with the versatility of Slow Tool technology for cost-effective production of free-form surfaces and microstructures.

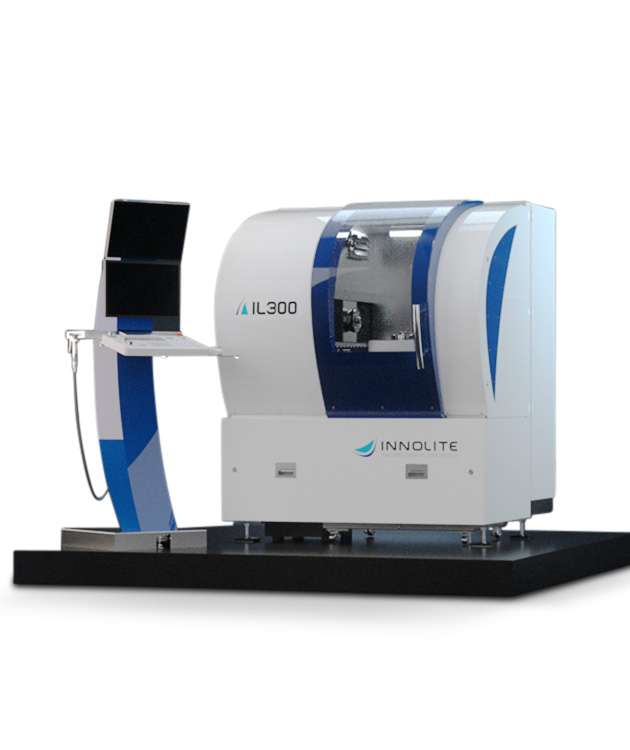

IL300

Partner: Innolite GmbH

Segment: CNC-Machines

Process: Turning

Segment: Ultra-Precision

The IL300 stands out as the top choice for ultra-precise diamond lathe, designed for efficient and versatile optics production. Its development aimed at enhancing productivity in ultra-precision technology. The machine features seamlessly integrated zero-point clamping systems, ensuring submicron precision, a durable stainless-steel housing, and a lightweight structure for optimal dynamics. It caters to various applications, spanning from traditional diamond turning to free-form fabrication and intricate microstructure creation, even enabling diamond turning of steel and infrared materials with ultrasound assistance (ILSONIC).

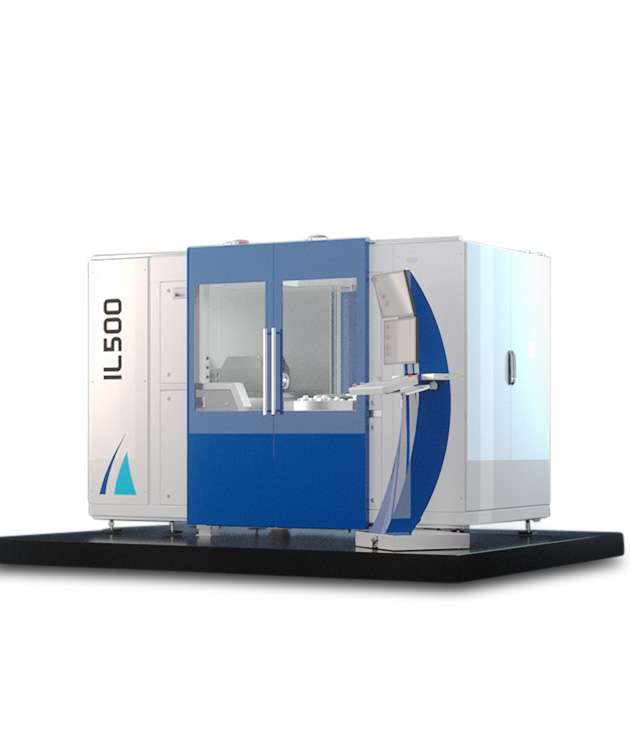

IL500

Partner: Innolite GmbH

Segment: CNC-Machines

Process: Turning

Segment: Ultra-Precision

In addition to large components with diameters of up to 500 mm, the IL500 offers unique options for simultaneous processing equipment or process parallelization. With three or four ultra-precision axes, spherical, free-form, and micro-structured optics can be efficiently manufactured. Integrated measurement technology enables inline surface characterization with direct compensation. This allows preprocessing steps and ultra-precise finishing to be efficiently combined with the highest levels of accuracy. Designed for robot loading, the machine is the ideal platform for automated series production.

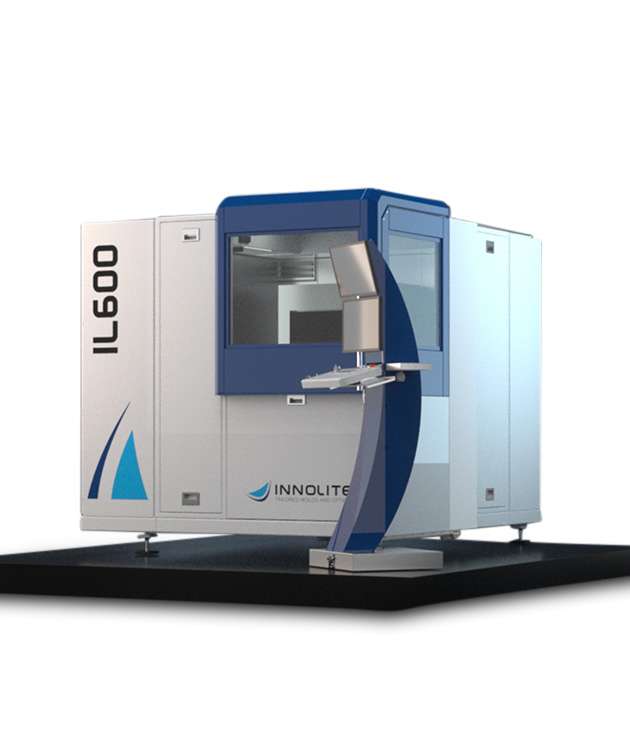

IL600

Partner: Innolite GmbH

Segment: CNC-Machines

Process: Turning

Process: Milling

Segment: Ultra-Precision

The IL600 is a four- or optionally five-axis ultra-precision machining center for highly productive optics production. The integrated NanoGrip zero-point clamping systems are world leaders in flexibility in diamond machining systems. The IL600 enables the combination of diamond turning and free-form turning, planing, and milling, as well as the grinding of optical surfaces. In addition to machining processes, we offer a range of contact and non-contact sensors that can be fully integrated into the machine and the control system for advanced component characterization.

IL1200

Partner: Innolite GmbH

Segment: CNC-Machines

Process: Turning

Process: Milling

Segment: Ultra-Precision

IL1200 is an ultra-precision 4-axis CNC vertical machining center designed for machining large optical mirrors up to 1.2 m in diameter with high accuracy. It can handle various materials such as metals, crystals, and polymers. The machine features advanced components like a self-leveling system, cooling systems, non-contact measurement, and diamond turning capabilities. The vertical spindle arrangement ensures precise alignment, and the software allows for machining different types of surfaces with high precision.